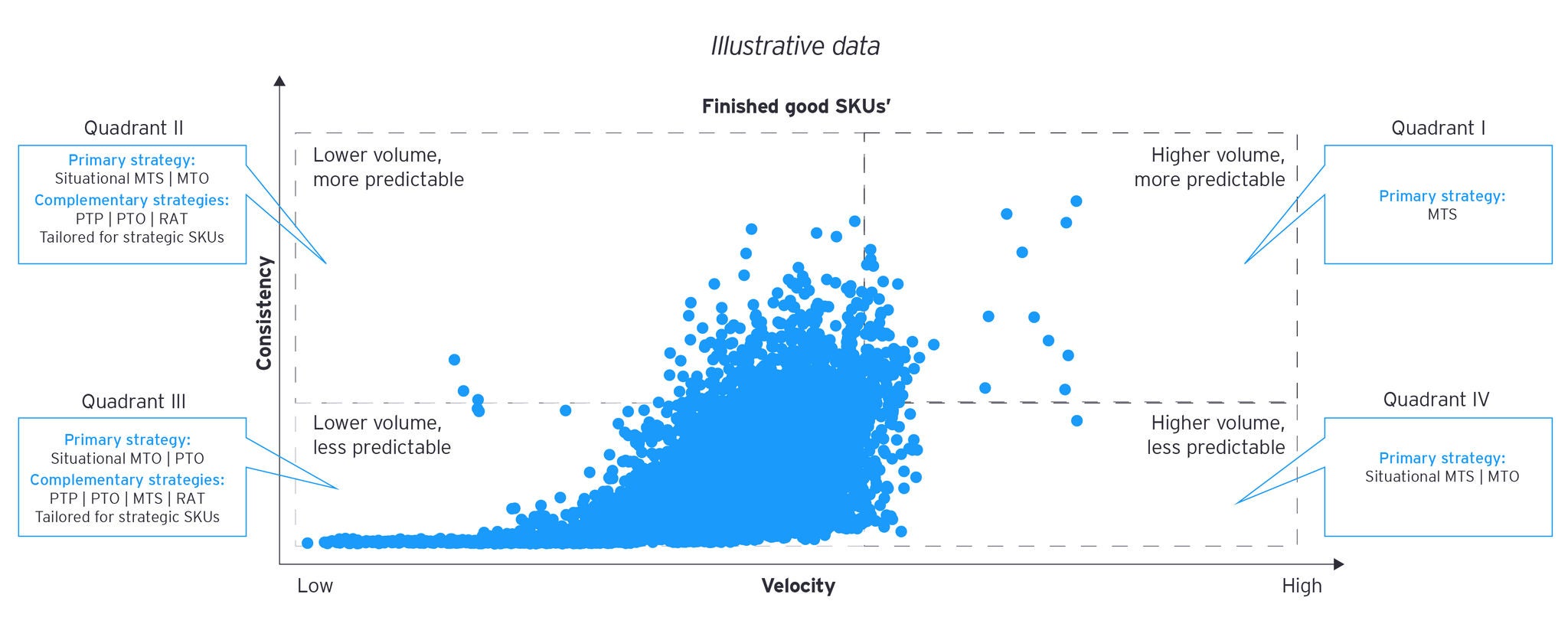

Product supply chain segmentation enables tailored marketing strategies and improved competitiveness. The quadrants show different levels of product complexity and provide a starting point for efficient alignment of the product strategy with supply chain management.

Such diverse product profiles, which are common among consumer products companies, contribute to supply chain complexity. Companies can create new efficiencies by considering product simplification together with supply chain restructuring. Both sides of the equation are important to making the approach work.

By aligning supply chains with the different product profiles, organizations can segment the supply chain by product type, making it easier to develop tailored marketing strategies that serve the business more efficiently. Without appropriate segmentation, the high-volume, high-consistency products can be interrupted or delayed by changes required to produce the lower-volume, one-off or specialized products. Capacity that is designed for one product segmentation may not be available or flexible enough to accommodate the other.

A window to understanding product complexity

EY-Parthenon teams have worked with clients to evaluate the SKU portfolio using predefined metrics that help prioritize products based on both market performance and manufacturing complexity. This starts by incorporating evaluation parameters that include supply chain and operational considerations alongside marketing and financial objectives.

While company leaders may be generally aware that their organization’s product mix could be simplified, a 2x2 portfolio segmentation matrix can help determine how complex the product portfolio is and can indicate how much the company might benefit from consolidating SKUs in a way that helps both commercial go-to-market and supply chain processes work better together.

With a more robust portfolio design in place, the “optimized” portfolio can be aligned across the supply chain in logical operational segments to create differentiated, parallel supply chains to meet the different needs of all products.

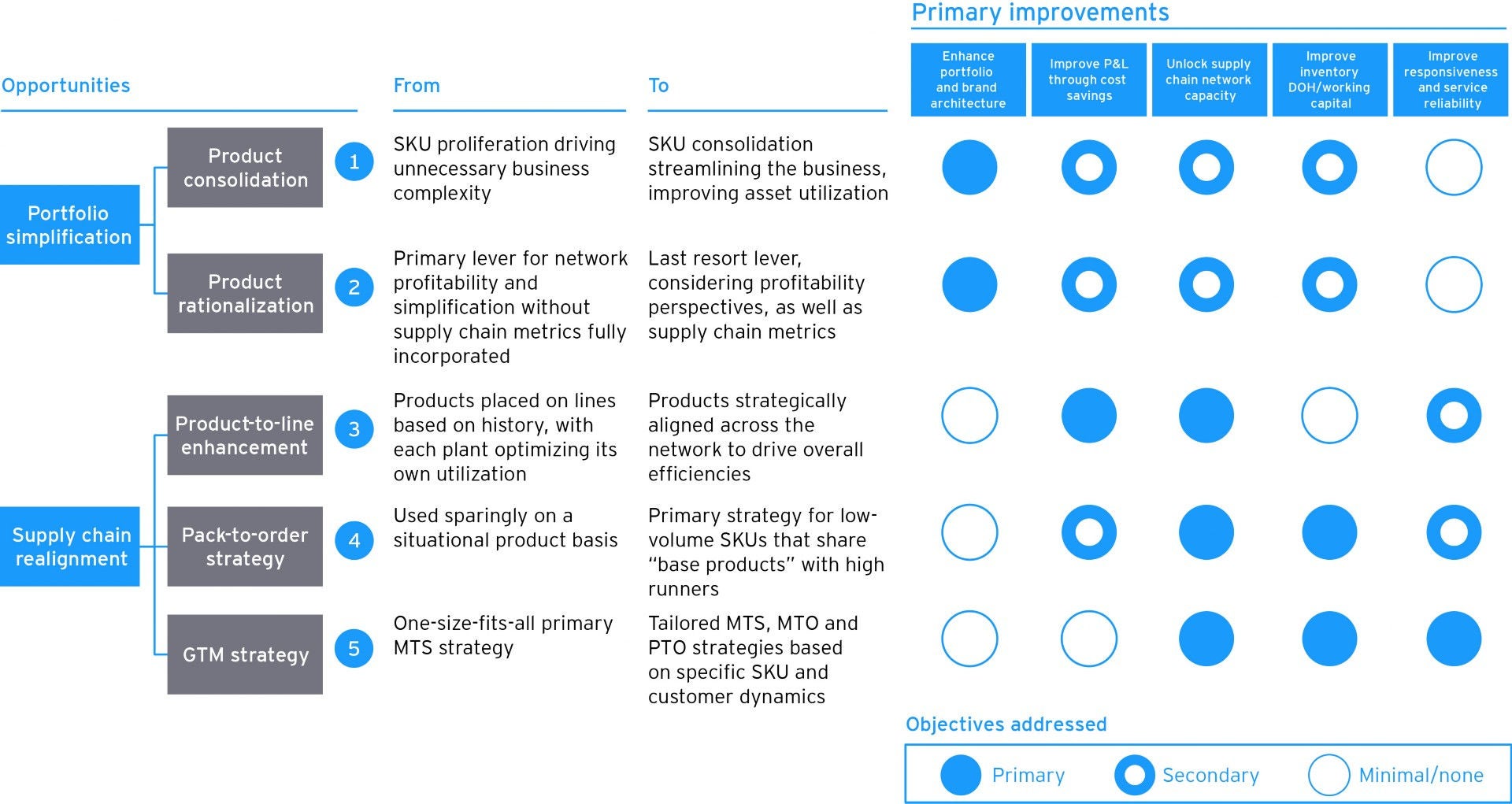

For the supply chain, realignment introduces a strategy for low-volume SKUs that share common components with high-volume products to create production synergies. The result is shifting a one-size-fits-all model to a tailored approach where manufacturing lines and stocking strategies are appropriately based on specific SKU and customer dynamics.

The portfolio changes can have a direct impact on supply chain efficiency by eliminating unnecessary product runs and changeovers. Planning around product families enables plants to change packaging for SKUs without bringing down the “main” production line. Production runs are longer and better utilized, helping unlock capacity to meet new demand and creating new revenue opportunities. The simpler product and manufacturing profile also helps improve supply chain resilience by reducing complexity and duplication.

The benefits for the commercial side, and the business overall, are equally clear. Product consolidation can help leaders define brand and product roles while also eliminating unproductive or duplicative SKUs. The result is a streamlined business and improved go-to-market and asset utilization, which in turn promotes sustainability and greater profitability due to cost savings. Sales are stronger, customers are better served, and the business can be more competitive overall (Figure 2).

Figure 2: Benefits of a coordinated product portfolio and supply chain strategy