EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients.

EY US and Ascend Elements explore the future of net-zero carbon emissions for the electric vehicle battery industry.

In brief:

- As the automotive sector confronts the mobility challenges of today and tomorrow, industry leaders recognize that electrification will play a major role.

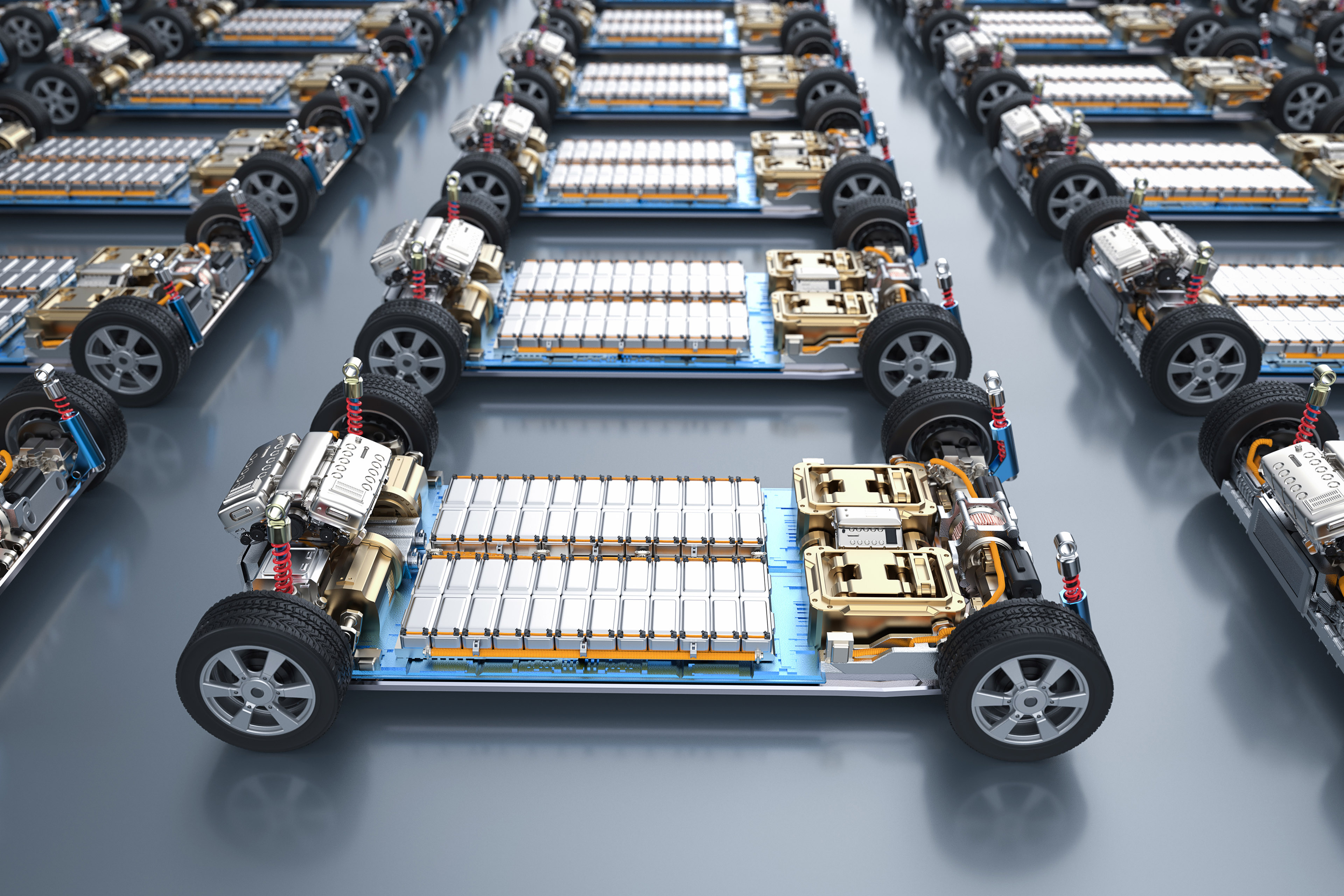

- A critical element of electric vehicles (EVs) is the battery. Some have called EV battery manufacturing a matter of national security for the United States.

EV adoption is gaining momentum worldwide.

Over the past few years, the automotive industry has been quite turbulent and the media has published provocative headlines about EV adoption challenges. Upon closer examination, however, it’s clear that a remarkable shift is happening globally as the automotive market electrifies. The following factors highlight this shift:

- Worldwide EV sales. Last year, EV sales, including plug-in hybrids, grew over 30%, accounting for around 14 million vehicles. That represents 17% of all global vehicle sales. One out of every six vehicles sold is an EV.

- US EV sales. In 2023, EV sales in the US grew over 50%. North American adoption of EVs has been a bit slower than other global markets with one huge challenge being that SUVs and trucks are harder to electrify due to their weight and the size of the batteries needed.

- EV battery costs. The cost of EV batteries has declined from $2,000 per kilowatt hour to less than $100. Looking ahead, there is the promise of $50 per kilowatt hour batteries that have a longer life, charge faster and are fully recyclable.

However, the EV market must still overcome numerous challenges.

As with any new technology, the EV industry must overcome a variety of challenges and disruptions. These include:

- Unstable supply chains. These impact product availability and costs, making it difficult for automakers to plan effectively.

- Manufacturing costs. The manufacturing costs associated with dedicated EV platforms are daunting. It’s difficult to make money by shifting existing platforms to different power trains.

- The EV charging infrastructure. In the US, charging station availability is hindering broader EV vehicle adoption. National Electric Vehicle Infrastructure (NEVI) grants are making more supercharging available in the United States.

- Circularity and sustainability. EV batteries play a central role in the sustainability of EV platforms. Through effective recycling, the industry can ensure a closed loop system and batteries can come back for a second life.

The path forward for the EV market will require innovative solutions. The road to affordability remains a key focus. Economies of scale will drive costs down and we should see continued maturation of the technology.

Ascend Elements is committed to making US EV manufacturing more self-sufficient and sustainable.

Many of the materials used by the EV industry are imported from different countries. To make US EV manufacturing more self-sufficient, it’s critical to produce more materials domestically and to recycle existing EV materials.

The EV battery manufacturing process is very energy and carbon intense. Ascend Element’s vertically integrated business model reduces 90% of the carbon emissions associated with the production of materials that go into every EV battery. That’s driven primarily by a patented Hydro-to-Cathode® process.

Ascend Elements begins by recycling the metals in scrap EV batteries and delivering an engineered material that goes into new EV batteries. Ascend Elements’ existing EV battery recycling facility in Georgia will provide the engineered materials to a new site in Kentucky that will produce enough materials to feed 750,000 EV batteries a year. The Kentucky facility will go live by the end of 2024 and enter large-scale industrial production in 2025.

To decrease business risks, Ascend Elements teamed with EY US.

As Ascend Elements created plans for its new Kentucky site, the team recognized that everything was theoretical. The company wanted to ensure that once the site was up and running, it would operate as effectively as possible. In response, Ascend Elements dedicated time and effort to developing a material flow strategy.

The industrial engineering team mapped out every material movement. Although their work was very thorough, Ascend Elements wanted additional validation from outside professionals. Together, Ascend Elements, with the assistance of EY US, engaged in a logistics simulation exercise to map all of the material movements.1

The relationship has been a logical one for EY US since the company is committed to sustainability and decarbonization of supply chains. Developing and sustaining a profitable and growing industry for recycling and remanufacturing of batteries is a focus area for EY US. The relationship with Ascend Elements started from a shared vision.

We met with different companies to see who would be best suited for providing validation of our material flow strategy. The collaboration with EY [US] was important to ensure that our plans were properly adjusted and fine-tuned.

Scaling up production of EV battery materials in the United States is a challenging proposition.

The majority of the world’s cathode materials are made in Asia. Local, state and federal governments recognize the importance of developing this capability in the United States and are providing support to companies like Ascend Elements.

For this new industry to thrive, Ascend Elements needs a network of advisors, including engineering, equipment suppliers and logistics companies. For most of the participants in this ecosystem, the field is completely new territory.

EY US is helping firms like Ascend Elements scale up their processes by overcoming challenges in a variety of areas, including:

- Raw material sourcing. The US is finding it difficult to secure stable supplies of raw materials for battery production, such as lithium, nickel and cobalt. EY US has significant experience in diversifying supply chains and mitigating supply chain risks.

- Regulatory compliance. It’s difficult to secure mining licenses and permits in the United States. It’s an area that is hard to break through, but the availability of raw materials depends on mining.

- Workforce. There is a pressing need for people to work in EV battery facilities. They need hard skills related to manufacturing, as well as soft skills related to communication and collaboration. EY US has a large practice focused on workforce strategies so that companies have the ability to grow.

The US hasn’t really built batteries on a large scale before. So much money is going into building gigafactories. A big part of this has been joint ventures working with different partners to allow technology to permeate into the fabric of the United States.

The long-term success of EVs and emissions reduction depends on circularity and minimizing industry risk.

Consumers worry about EV batteries ending up in landfills and a majority of Americans (56%) fear that old EV batteries will cause toxic landfills.

Ascend Elements has a clear vision and roadmap for circularity, but it’s a long road ahead. The Kentucky site will be a game changer and the company recently announced a joint venture in Europe to expand operations.

The business of EVs comes with its share of risks. The goal of EY US is to de-risk execution plans by developing the right strategies for technology, going to market, talent management and more. Working with companies like Ascend Elements and others is a core focus for the firm.

As the world transitions to a cleaner future, industry leaders must stay focused and find ways to participate in this shift.

There’s no denying that the energy transition is happening, though it’s unclear how long it will take for markets to react. It’s essential for leaders to focus on the data. The transition won’t be linear, but the trend won’t change. To address consumer concerns about EVs, more education is needed, as well as better infrastructure and improved vehicle affordability.

Opportunities exist for companies to get more involved in meeting the unmet current and future EV demand. Companies like Ascend Elements would love to have more stakeholders playing a role, such as equipment manufacturers, logistics providers and more. Circularity is mandatory from a regulatory standpoint and an economic one. To help the planet, it just makes sense to use EV batteries over and over.

Summary:

The EV market is expanding, reaching 17% of total sales worldwide. However, the industry needs to address concerns around unstable supply chains, high manufacturing costs, insufficient charging infrastructure, and the need for sustainable battery recycling. Ascend Elements and EY US are working together to enhance EV manufacturing self-sufficiency through domestic material production and recycling. The industry's success hinges on circularity and risk minimization, with a focus on education, infrastructure, and affordability to meet growing EV demand and regulatory requirements.

Related articles

The next big thing in EV production

Learn how EV companies are adapting and overcoming various manufacturing challenges, such as high costs, scalability and efficiency.

Why there is much more to sustainability than building EVs

In this episode, Andrea Weinberger discusses why the automotive industry needs to embrace a wider sustainability agenda. Learn more.

Reframe your strategy: The great automotive value shift

As value is shifting toward new disruptive areas, the auto industry needs to quickly adapt and unlock the emerging revenue opportunities. Learn more.