EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Limited, each of which is a separate legal entity. Ernst & Young Limited is a Swiss company with registered seats in Switzerland providing services to clients in Switzerland.

Explore our Offerings

-

The Circular Economy solution of EY Sustainability enables circular product design, business model innovation and ecosystem redesign of businesses.

Read more

Circularity pioneers: Existing innovation in MedTech

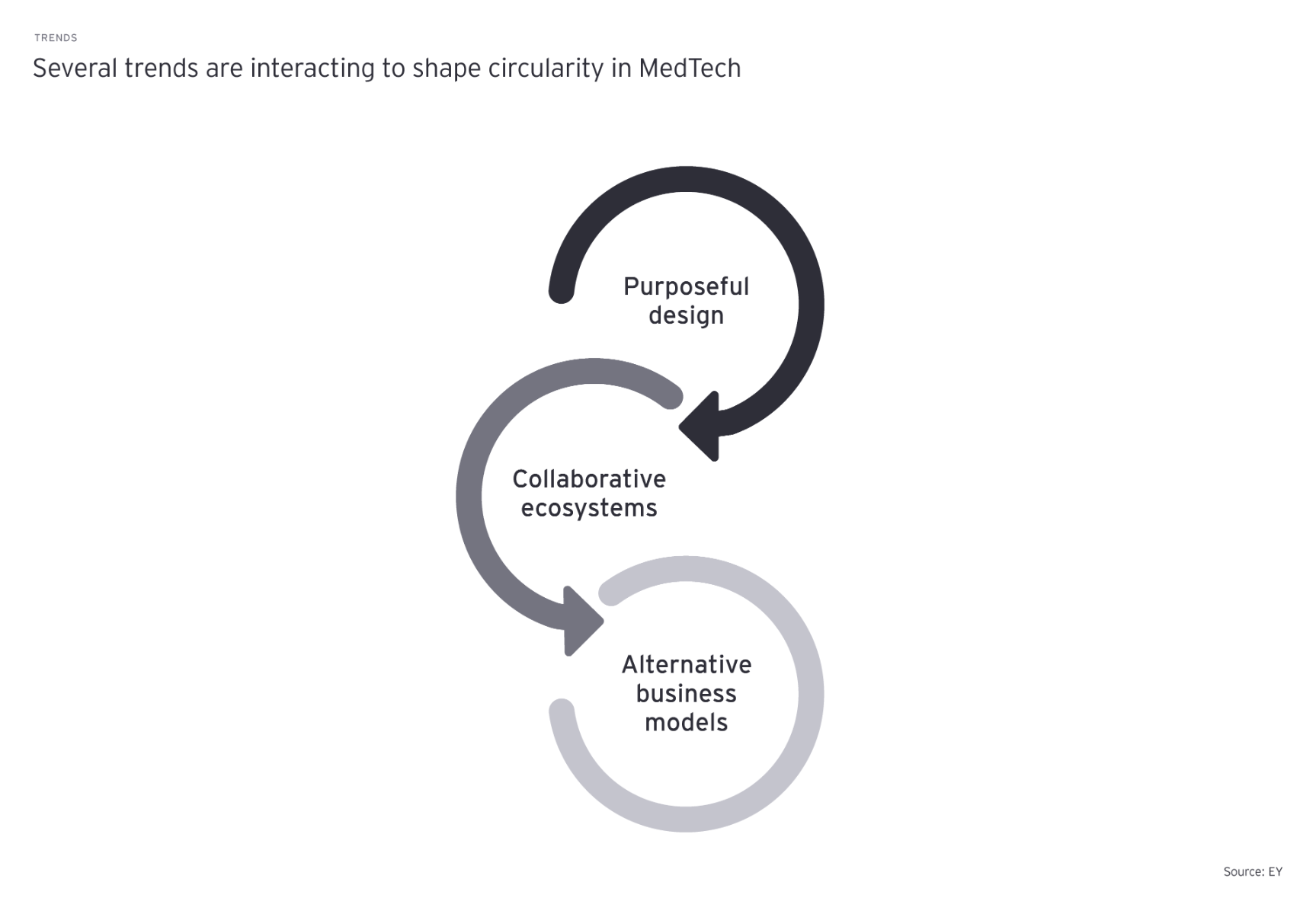

Several circularity pilots in the MedTech industry are showcasing the potential for innovative solutions that not only address environmental concerns, but also foster resource efficiency and economic viability. Some MedTech companies have already taken steps to enhance their environmentally friendly offerings to customers while reducing their own carbon footprint.

1. Circularity by refurbishment: Lifetime extension for small- and large-scale instruments

High-value instruments such as MRI machines, ultrasound machines and other imaging equipment are increasingly retrofitted and refurbished to achieve significant lifetime expansions, ensuring availability of state-of-the-art instruments while reducing the demand for virgin materials. With the progressing of refurbishing technologies, new operational models with a shift in ownership emerge, such as product as a service approaches.

2. A case for circular design: Design of single-use items

Given the inherently stringent hygiene standards, it is still often most advisable to design certain advanced devices as single-use items. Otherwise, significant safety and economic compromises must be accepted. By incorporating modular components, materials that are easier to disassemble, and implementing take-back programs, MedTech companies can enhance the recyclability and resource efficiency of such devices. Furthermore, such initiatives contribute to reducing electronic waste and promoting a circular economy in the industry. These principles have been applied to the design of surgical staplers, bronchoscopes and respiratory equipment. In other cases, it is even possible to choose an alternative base material for a design. A leading manufacturer of surgical disposables, for example, has introduced a range of surgical drapes made from bio-based materials instead of plastics. This change has reduced the overall environmental impact of their disposable products.

3. Saving costs through re-using costly materials: Catheters

Catheters are another area where circularity can drive innovation. Exploring the use of recyclable or reusable precious metals for catheter manufacturing can help reduce the environmental impact associated with single-use medical devices. By aligning material choices with circularity principles, MedTech companies can contribute to waste reduction and a more sustainable healthcare system.

It all comes down to rethinking product design and utilizing the power of design for circularity right from the beginning of the product life cycle. Only such rethinking allows for harnessing the full potential and a systemic change with a long-term vision. Successful pilot projects are an effective way of promoting this way of thinking and should encourage other players to follow suit. The emerging space allows players to position themselves with new innovations, accompanying intellectual property and new cross-industry collaborations.

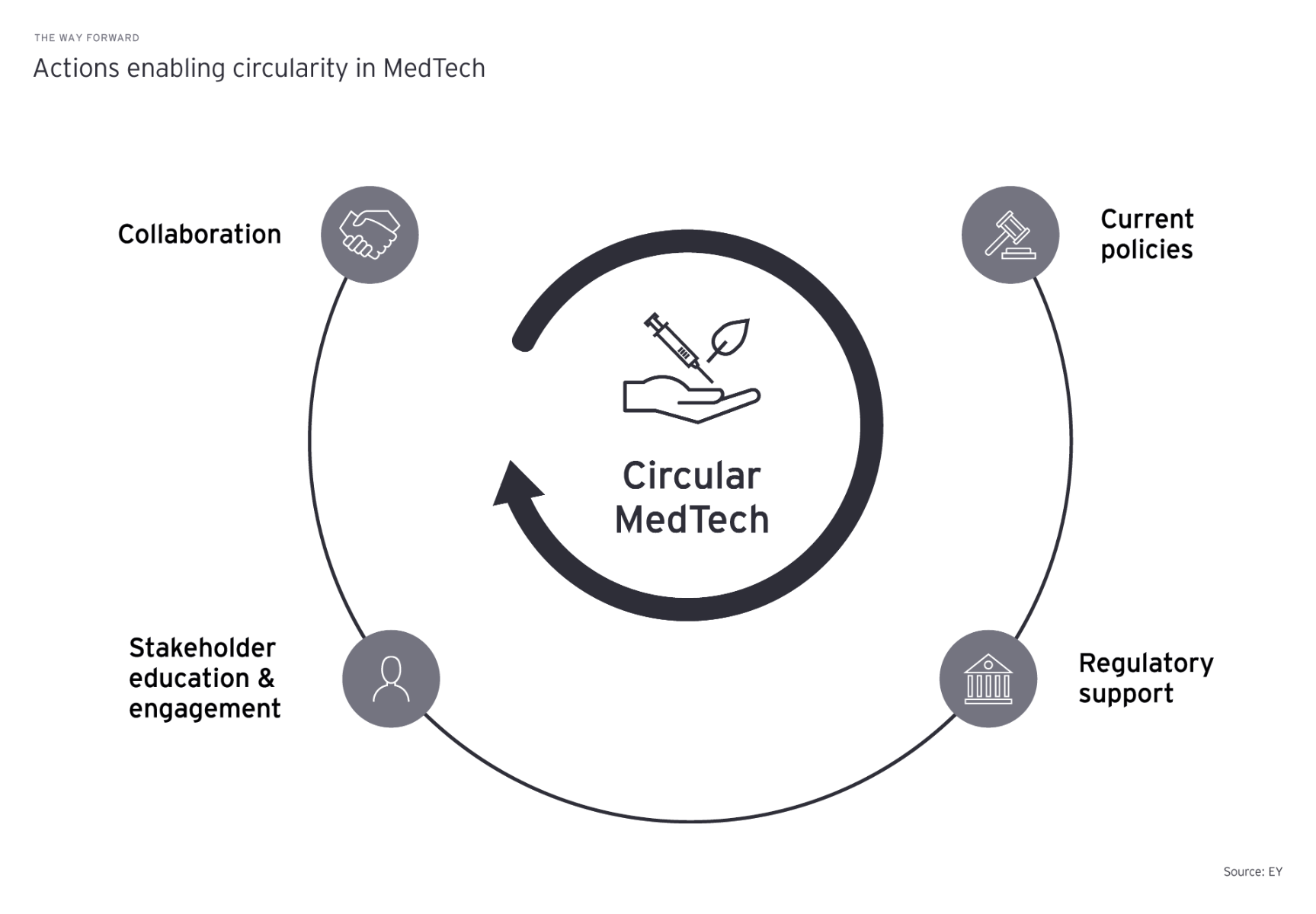

Conclusion: Shaping a sustainable future for MedTech

The MedTech industry stands at the forefront of innovation, driven by the principles of sustainability, circularity, and product design. Through circularity pilots, MedTech companies are exploring new possibilities for waste reduction and resource efficiency. However, to fully realize the potential of circularity, supportive regulations are essential to facilitate product take-back initiatives and to reduce barriers in the market for refurbished goods. Additionally, circular business models offer cost-effective alternatives that align with limited hospital budgets, contributing to a more sustainable and resilient healthcare system. Altogether, MedTech companies that choose to adopt circular product designs can make a real difference in the world while also maintaining profitable operations. This is a powerful motivator for many companies in healthcare, an industry more purpose-driven than many others.