EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Limited, each of which is a separate legal entity. Ernst & Young Limited is a Swiss company with registered seats in Switzerland providing services to clients in Switzerland.

How EY can help

-

Our Government & Public Sector community brings together more than 20,000 EY people from over 100 countries. All of us share a passion to help governments work better for their people.

Read more

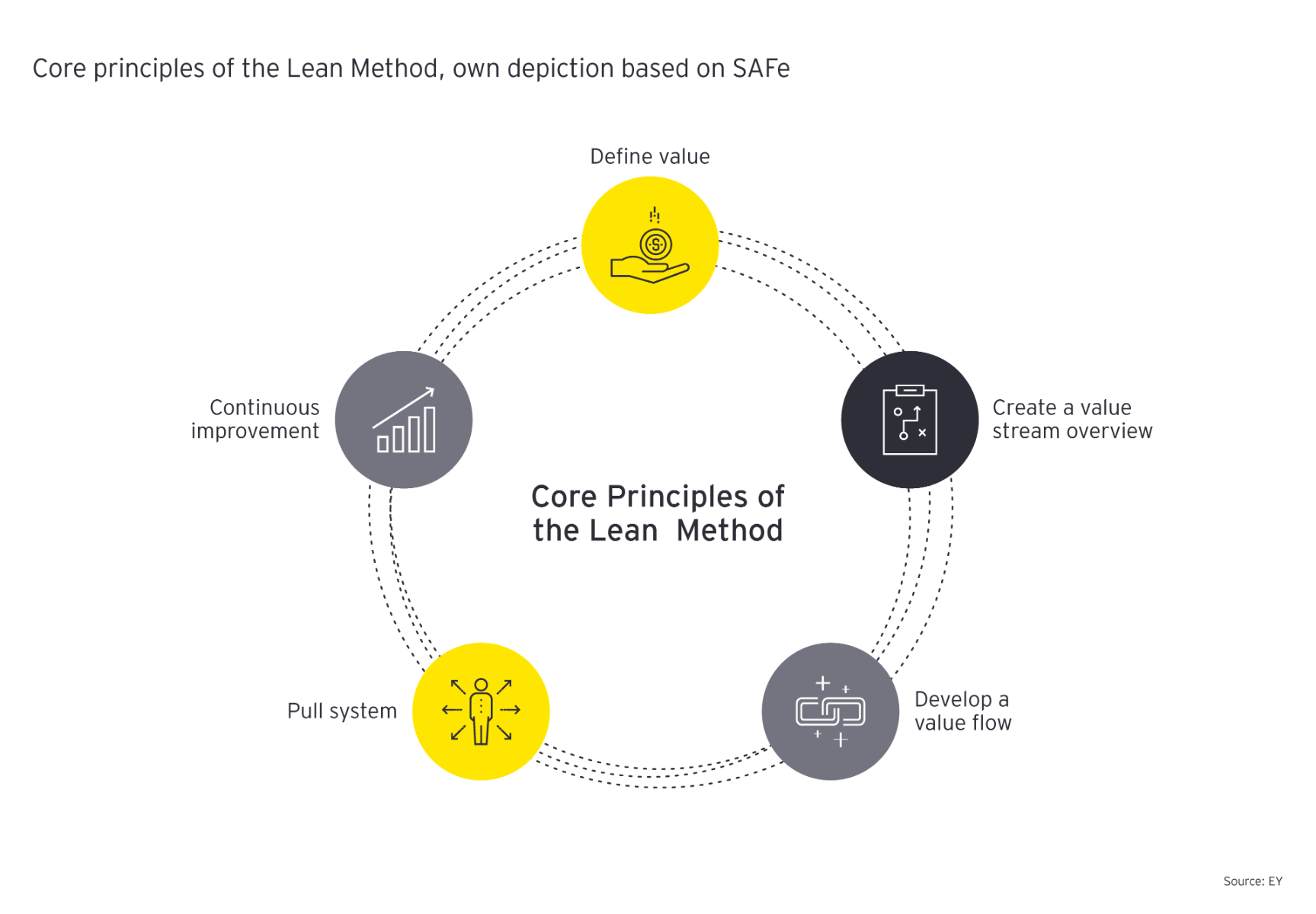

- Define value: The first step is to define the value of the product or service and communicate it clearly to all stakeholders.

- Create a value stream map: A value stream analysis or value stream mapping (VSM) helps to compare the current workflow with the ideal workflow between the project initiation and project completion phases and highlight inconsistencies.

- Develop a value stream: The flow principle is one of the central elements of Lean thinking and aims to eliminate waste. The inconsistencies mentioned in the second point must be addressed and eliminated in order to achieve the smoothest possible process.

- Pull system: Alongside the flow principle, the pull principle is another key element of Lean thinking. The aim is to ensure that activities only arise when there is an actual need for them and not on the basis of forecasts. This reduces dependence on actual demand and avoids wasting resources.

- Continuous improvement "Kaizen": The "Kaizen" principle encourages employees to achieve a state of continuous improvement. The four previous Lean principles are constantly reviewed and scrutinized.

LPM is a further development based on the Lean Method. It combines the five Lean principles with the way organizations and companies plan their strategies and finance their investments. LPM offers a dynamic and goal-oriented approach that promotes a continuous flow of value creation. The goal of LPM is to maximize value creation. LPM focuses on managing the backlog to focus on the highest value goals of the company or organization. By clearly prioritizing the projects and tasks that generate the most value for citizens and the organization, value creation is maximized.