EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients.

How EY can help

-

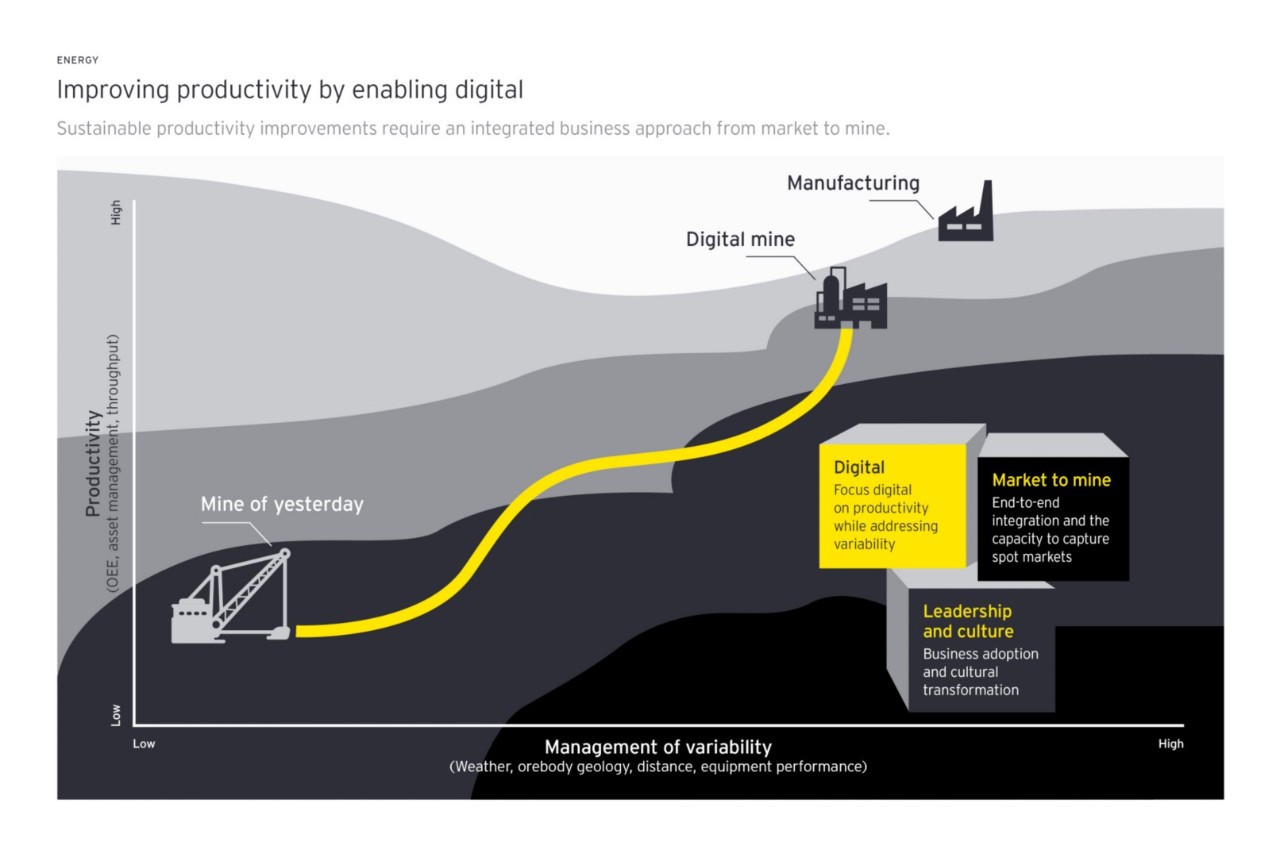

Our Digital Navigator takes an end-to-end approach to the development of a digital vision, strategy and actionable road map for mining and metals companies.

Read more

Eight questions that can help companies find their way forward

The same rigor that underpins other major change or expenditure initiatives needs to strengthen digital transformation, too. Before embarking on the digital journey, a sober assessment of the way forward is required.

Start by asking yourself these questions:

- Do we have an alignment between the digital vision and the business strategy?

- How long will it take, and what is a reasonable estimate of cost?

- Do we have a clear business case to support the change?

- What capability do we need, and how does this compare with our current resourcing?

- What are the packages of work, at an appropriate level of detail, required to move from our current state?

- What is the level of cultural support, and have we addressed critical elements of the change?

- Do we understand how the new digital operating model will look?

- Have we tested this with those who understand the operations in depth?

Given the digital disconnect, the right approach to transformation is crucial. The industry does not need another cheerleader but requires a navigator in what is a difficult but highly prospective journey.