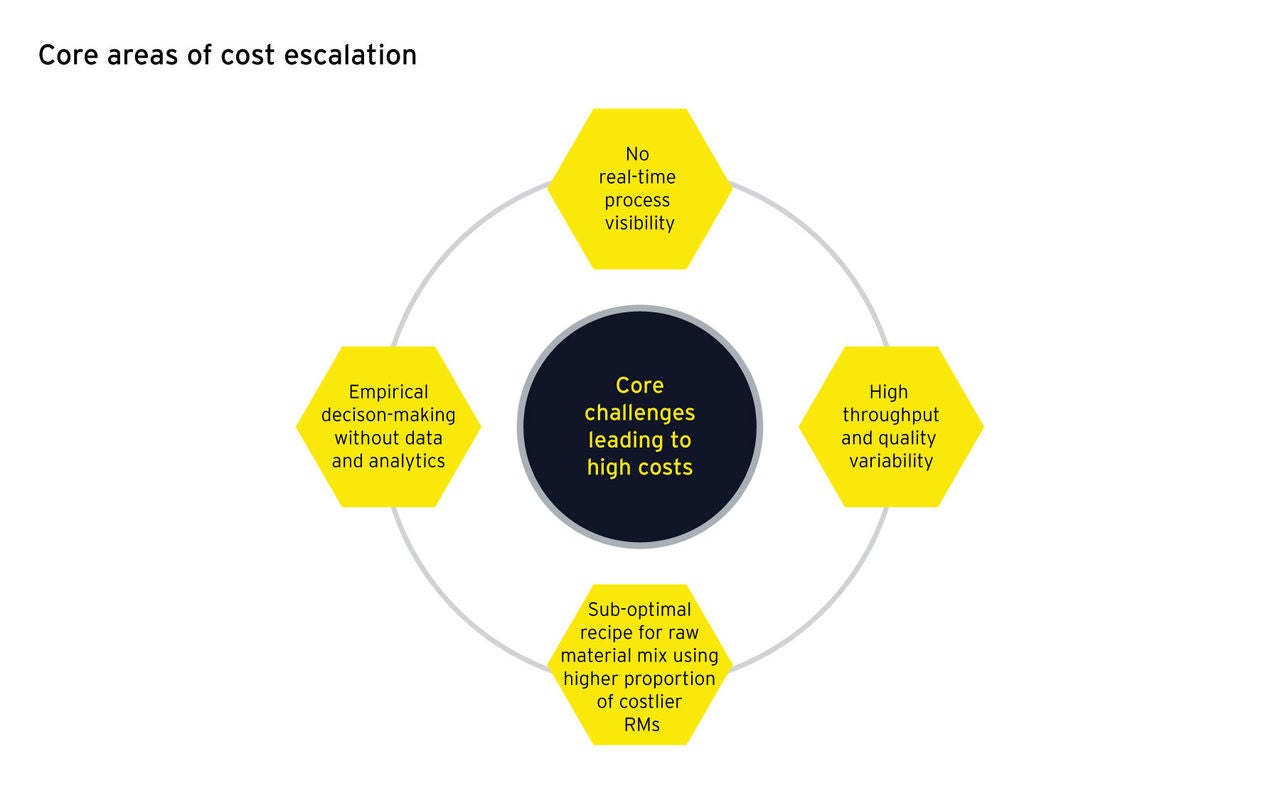

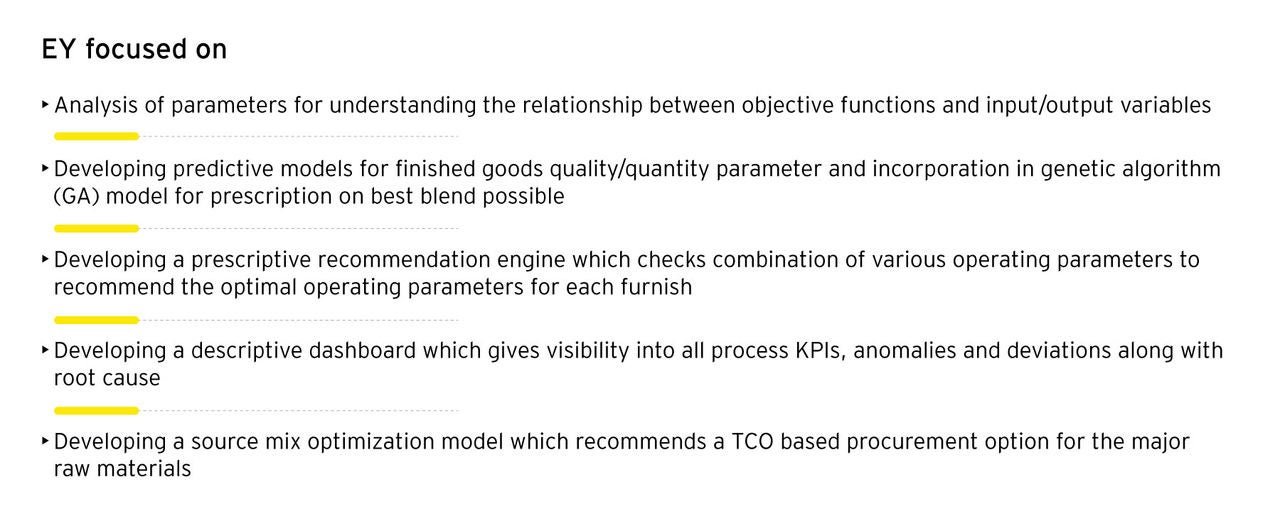

The AI-enabled “Manufacturing Intelligence Platform” is a digital representation of a production system that spans across the complete production line, is updated from real time data, uses simulation modelling, predictive and prescriptive analysis to aid business and process owners in decision making.

The company witnessed improvements in efficiencies across various processes and reporting across various functions. Acknowledging that raw material consumption constituted over 80% of production costs, the “Manufacturing Intelligence Platform” allows raw material consumption monitoring which significantly helps reduce costs through scientific modeling, scenario simulations and decision-support.

The AI-enabled solution helps the company realize unprecedented improvements in efficiency and costs.

The company is currently in the process of enhancing value from the solution, including benefit tracking and performance monitoring, implementation of individual initiatives, onboarding vendors and suppliers, and enhancing technological foundations.