Chapter 1

Status of 3D printing in Europe

Who are the key trends, therapeutic areas and players in Europe and abroad?

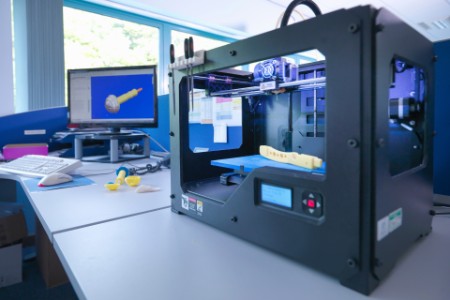

3D printing allows to make personalized implants in different medical fields, the most common applications being for neurological, plastic, reconstructive, oral and orthopedic surgery (Source: Wohlers Associates, 2022). In 2019, Europe was the region with the most (55%) 3D printing firms, followed by the Americas with 32%, and Asia with 13%. At a country level, the USA have the highest number with 29% of all companies, and Germany is second with 24%. (Source: Global EY report 2019). The global trends identified by EY are implants, external wearable devices and clinical study devices, all expected to grow between 16 and 21% between 2019 and 2026.

In Europe we identify the main players as the dental and orthopedics fields. For many years, the dental industry has been finding new ways to incorporate 3D printing technology. Due to the small, intricate, customized and high-value nature of dental parts, 3D printing has been thoroughly researched and used by obtaining data from dental forms, intraoral scans, and radiological imaging of the patient's jaw. One of the great successes of the dental industry is the impression of orthodontic aligners and the leader is US-based Align Technology. (Source: Wohlers Associates, 2022).

Orthopedic prostheses used to be made in standard sizes, yet each human body is unique. Today 3D printing allows orthopedics implants to be personalized to each individual, whether it is a knee replacement, a hip cup or a spinal device. The custom prosthetics and implants represent a large share of the global 3D printing market and big players in the European market include SLM Solutions Group AG (Germany) and Materialise NV (Belgium).

Looking at leading countries in the field in Europe, we observe that in the field of vision care, the first 3D-printed prosthetic eye procedure was performed in 2021 at the Moorfields Eye Hospital in the UK. (Source: Wohlers Associates, 2022). In Switzerland, the Swiss m4m Center which focuses on 3D printing for medical applications receives funding from the national government, and the center's main objective is to encourage the advancement and utilization of 3D printing in dental, orthopedic, spinal, and traumatology surgeries. In 2019 in Germany, a medical division of the Mobility Goes Additive (MGA) network was created, to boost 3D printing in medicine by enhancing the technological knowledge amongst members. Globally, the biggest players are in the USA and Israel and include Stratasys Ltd, Carbon, Formlabs, Desktop Metal and Biomedical Modeling. (source: EY Global Report 2019).

The growth of the 3D-printed medical devices market is fueled by research and funding initiatives aimed at accelerating the development of 3D printing technologies and products. Noteworthy examples include nTopology, a US company that secured $40 million in funding in September 2020 for the advancement of their software platform. Similarly, the University of Huddersfield received a funding of $2,6 million from Innovate UK in March 2019 to develop a cutting-edge electron-beam additive manufacturing (EBAM) printer. (Source: Straits Research)

Chapter 2

Challenges in 3D printing and the importance of M&A

What are the current and expected future challenges? What are the investments from medical devices in 3D printing companies?

The challenges can be divided into four main groups: high prices and investment, technological limitations, business challenges and regulations. High prices of 3D printing systems are a widely cited barrier to the adoption or extension of the technology. The build envelope and product size are also limitations for 3D printing, making it applicable mainly to smaller parts. Limitations on materials and multi-materials and concerns about product quality are also key concerns for patient safety. The market for 3D printing is experiencing a talent war as the demand for advanced experts with extensive 3D printing in this niche area continues to escalate. Another challenge is integrating 3D printing into existing systems and structures, which requires careful planning and integration into IT infrastructure. Additionally, intellectual property issues may arise, such as patent infringement, as 3D scanning devices make it easier to copy designs and create similar products. Currently, there is no specific legislation addressing 3D printing infringements.

Mergers and acquisitions (M&A) have the potential to mitigate some of those challenges. For instance, some companies that lack experience in 3D printing have partnered with specialized service providers who can offer access to different technologies and cover related activities throughout the supply chain. Mergers and acquisitions also play a role in driving innovation. In January 2021, Stryker acquired OrthoSensor, Inc., specializing in sensor technology for total joint replacement. This acquisition positions Stryker with advancements in smart sensor technologies, including smart implants, intraoperative sensors and wearables. Another collaboration took place in April 2022 when eCential Robotics joined forces with Amplitude Surgical to develop a robotic knee surgery solution. Market-leading products are also making waves in the industry: in August 2021, the FDA granted De Novo classification to the Persona IQ Smart Knee by Zimmer Biomet, cementing its position as a leading product in the market.

M&A have the potential of shaping the future of the industry and one of the primary drivers of M&A activity in the 3D printing industry for medical devices is the pursuit of innovation and technology. With the financial obstacles and growing demand for customized solutions within various industries, 3D printing has emerged as a transformative technology that has the potential to revolutionize the way companies approach production and innovation: M&A can be a game changer in facilitating the development of new technologies and bringing together complementary strengths of different companies, thereby accelerating innovation and growth. M&A can offer companies the opportunity to access new markets, geographies, and customer segments, especially with the growing demand for affordable and innovative medical devices due to aging populations and rising healthcare costs. For example, Aprecia Pharmaceuticals, a global leader in 3D printing of medications and the only FDA-validated commercial-scale drug development company, has produced the first 3D printed tablet for patients with swallowing difficulties (source: Aprecia Pharmaceuticals). Aprecia has also announced a partnership with Glatt Pharmaceutical Services, which will allow them to combine their expertise in 3D printing with Glatt's proficiency in pharmaceutical powder processing technology.

EY anticipates that transaction multiples will remain at a high level in the near to mid-term, reflecting the positive outlook for technology and the expected growth of the expanding market as adoption rates increase and costs go down. These rising 3D printing companies are transforming the M&A market by breaking down industry boundaries and creating an open system in which all parties interact within a network. As a result, raw materials suppliers are now selling directly to end customers instead of intermediaries. There are three primary reasons why companies form partnerships. Firstly, they do so to innovate and discover new applications, particularly for end-user products. Secondly, partnerships are formed to achieve technical enhancements such as improvements in machine speed or product quality. Lastly, companies may partner to create new materials that enable them to quickly identify new applications. (source: Global EY report 2019).

Chapter 3

The future of 3D printing in medical devices

How can companies gain a competitive edge?

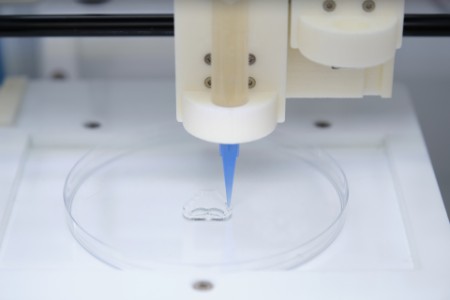

The different applications of 3D printing provide an opportunity for companies to transform their business models, reposition themselves in the value chain, or gain a competitive advantage by leveraging this innovative technology. The technology can enable companies to meet customer expectations better through personalized and cost-effective products and[FB1] the widespread adoption of 3D printing through large-scale production can help companies increase efficiency, reduce costs, and achieve economies of scale, ultimately leading to a more profitable and sustainable business model. A further novelty that will make personalized healthcare grow even further is if parts can adapt to environmental conditions and change shape. In 2021, a group of medical professionals in the USA used personalized 3D printed implants for three individuals suffering from tracheobronchomalacia (a condition that results in the excessive narrowing of air passages during regular breathing). The implant can expand as the airway grows and gets absorbed by the body. This type of 3D printing is referred to as 4D printing and will be the future that lies ahead of 3D printing. (Source: Wohlers Associates, 2022).

EY has categorized the maturity levels in the industry on a scale of 1 to 4, reflecting the extent to which companies have embraced 3D printing. Level 1 denotes inexperienced companies, while level 4 signifies companies that have strategically integrated 3D printing and established alignment throughout their entire organization.

When assessing these levels, we observe that MedTech companies tend to operate at high levels, yet the extent of strategic implementation varies, with some companies having a strategy in place only within specific departments and others having embraced the technology organization-wide.

So what benefits await MedTech companies that have already attained the highest maturity level? There are clear ways to bring these companies to the next level by further leveraging their strategic applications to pursue either growth or efficiency strategies. A couple of use case examples include achieving substantial process optimization within the supply chain by eliminating intermediate steps, and eliminating the need for additional surgeries by creating tailor-made prostheses instead of off-the-shelf replacements.

What challenges does 3D printing solve:

In addition to producing personalized medical devices and solving the challenge of fitting a patient's unique needs and anatomy, 3D printing can also reduce the cost of producing medical devices, as it eliminates the need for costly molds or tooling. This can make medical devices more accessible to patients who may not have been able to afford them before. 3D printing also allows to reduce the time it takes to bring a new medical device to market, because it allows for rapid prototyping and testing, which can help speed up the design process. Creating anatomical models for surgical planning with 3D printing can help surgeons better understand a patient's anatomy and plan for complex surgeries. Additionally, there is a growing focus on sustainability and responsible manufacturing practices in the medical industry and 3D printing has the potential to significantly reduce waste and improve resource efficiency compared to traditional manufacturing processes.

3D printing also has the potential to improve social outcomes by enabling more affordable and accessible medical devices, particularly in developing countries where access to traditional manufacturing technologies may be limited. Overall, 3D printing can revolutionize the medical devices sector by allowing for the creation of personalized and complex devices that can improve patient outcomes and reduce costs. The medical devices industry is critical to the health and wellbeing of patients, and 3D printing has the potential to greatly improve the quality of care.

Will the healthcare industry harness the full potential of 3D printing to advance both sustainability and social responsibility in the production of medical devices?

Summary

3D printing in medical device manufacturing has come a long way in the last decade, enabling cost-effective personalized products and improving patient outcomes. However, the technology still faces significant challenges such as high costs, technological limitations, and regulatory hurdles, which may hinder its full adoption in the industry. Despite these challenges, continued innovation and investment in the technology could potentially reshape the medical devices industry and pave the way for a future of more personalized and accessible healthcare.

Acknowledgements

We would like to thank Clémentine Bittar, Chris Griffin, Nino Nikolovski, Finn Beyer, Tamo Pfeiffer and Jay Preston for their valuable contributions to this article.