EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients.

Related article

Eight ways to boost sustainability in your supply chain

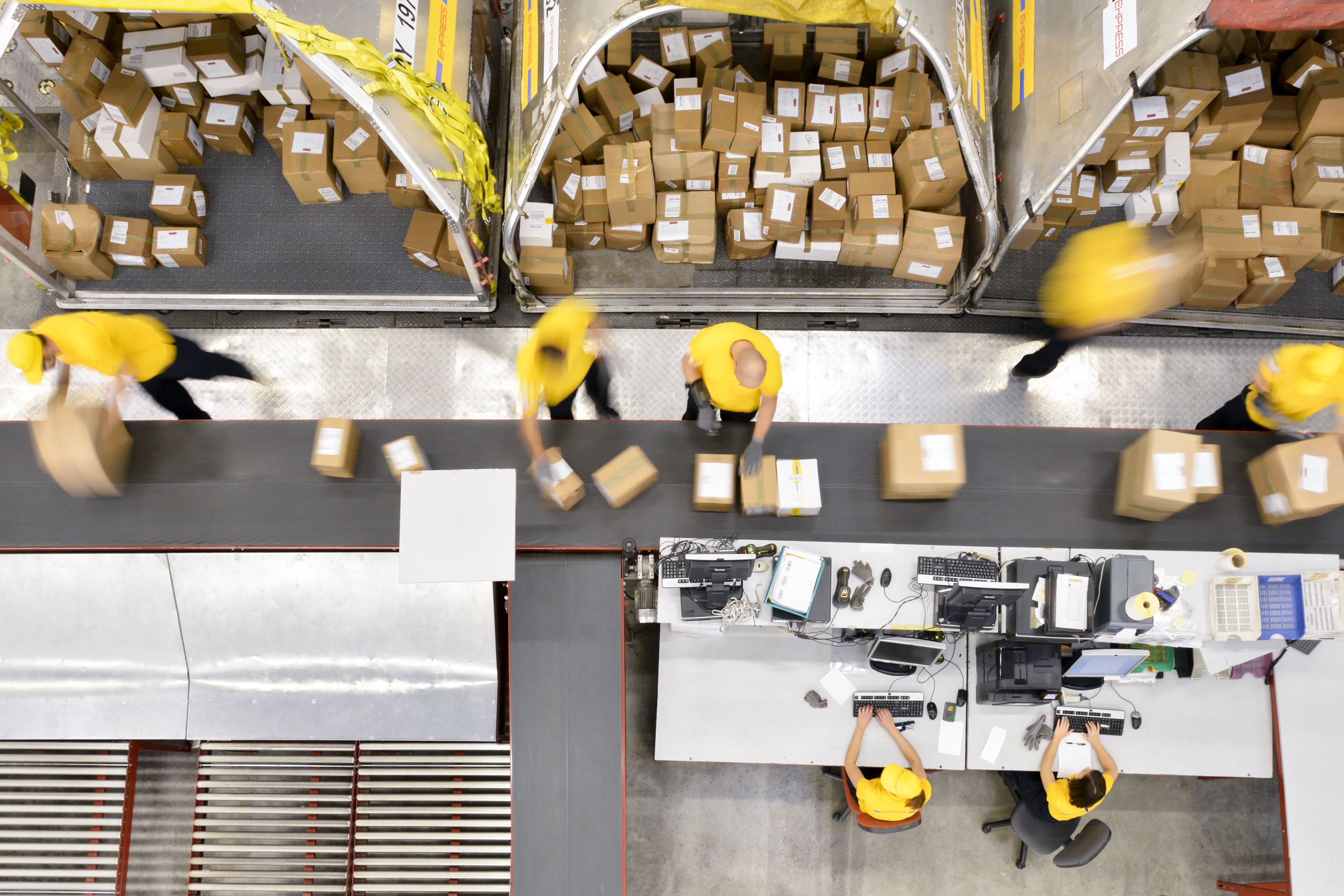

Supply chains have become global and highly complex. Building and maintaining a resilient supply chain is crucial in a fast-changing world.

EY teams also assessed the frozen-food producer’s existing equipment, manufacturing efficiency and continuous improvement processes alongside alliance partner Procter & Gamble (P&G). The team’s zero-loss analysis identified over $175m in value from incremental cost savings and profit margin, saving millions that can now be devoted to new capital investments in production lines.

Finally, EY teams analyzed logistics to identify cost-improvement areas including transportation and warehousing, vendor sourcing, network design, and redundant shipments. An evaluation of non-value-add activities revealed that some products were being handled as many as five times before reaching the consumer. By removing unnecessary manual tasks, products can now reach their destination more efficiently with only a single contact point.

Overall, EY teams consolidated distribution centers, shortened shipping times, optimized distribution, and altered freight sourcing options, realizing cost-saving potential of up to 27% of their annual logistics spend.

“Our team zeroed in on the key areas to make a significant impact, focusing on the fundamentals of complexity reduction, productivity improvement and cost savings,” said Chris Cookson, US West Supply Chain and Operations Consulting Leader, Ernst & Young LLP. “By focusing on these core areas, the client has built the foundation for success in their supply chain and transformed their business.”