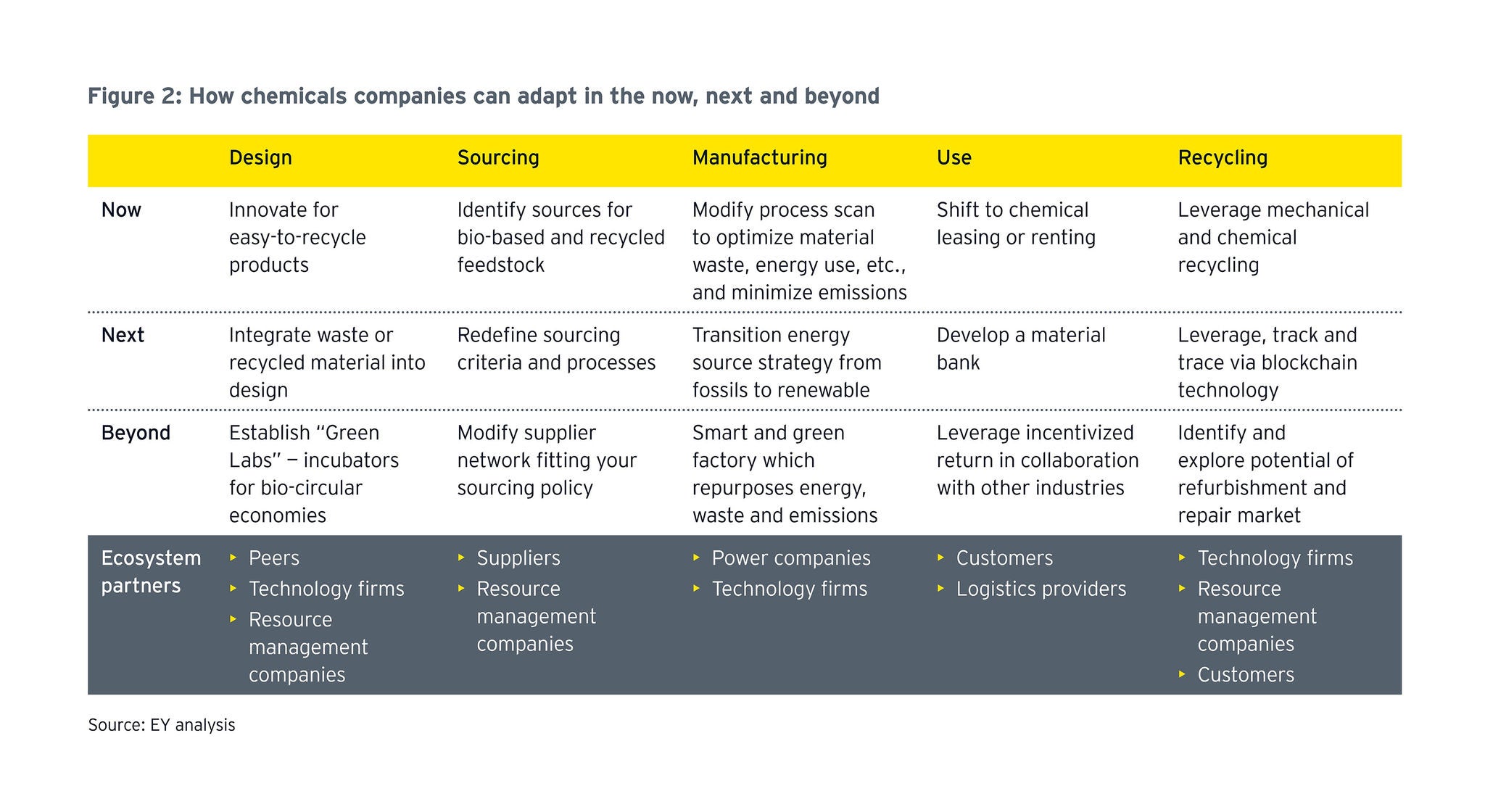

What’s next? (6 to 18 months) — integrating advanced digital technologies within the circular economy

Once the company has top-down buy-in on the importance of circular economy principles and how the organization can support them, product design should come to the forefront, as a new lens can be taken to re-evaluate existing products and services. Directly engaging your customers in conversations about their sustainability objectives can spur new ideas and opportunities to consider the viability of alternate partnership models, such as chemicals leasing.

Advances in digital technology could also be leveraged to enhance transparency and credibility of circular value chains. Use of artificial intelligence and blockchain solutions for tracking and tracing material can provide increased confidence in the true source and circular nature, which a customer may be paying a premium for.

Recycled content certifications are another promising mechanism to do this. Whether for mechanical or chemical recycling, committing to a fully certified value chain (in alignment with your partners) strengthens the commercial value of the end product, and provides options for participating in potential credit-trading schemes (such as for plastics) as they emerge and mature.

Looking beyond (18 months to 5 years) — developing a wider circular community and culture

Once a chemical company has solidified its circular ambitions and has identified new revenue opportunities to do so, it should focus on encouraging the growth of the broader circular economy industry. Startup accelerator programs and incubators are one way a more established company may look to source new ideas and technologies, while offering a framework for replicating and scaling business models and technologies that demonstrate promise.

Investing in solutions to address upstream and end-of-life product challenges is another mechanism for companies to partner and magnify their impact. Strengthening collection, sorting and waste infrastructure, whether through voluntary or regulated requirements, provides the opportunity for a producer to obtain and reuse its own raw materials. Partnering with brands and retailers to address harder-to-recycle products, such as apparel, toys, and automotive parts, could offer significant goodwill for companies that can identify commercially viable models to incentivize return, repair or refurbishment.

Lastly, numerous cross value-chain initiatives, alliances, and marketplaces have formed in recent years to bring together entities interested in addressing issues of waste and reuse. The Global Alliance on Circular Economy and Resource Efficiency (GACERE) is one such alliance worthy of consideration. Formed in 2021 by the EU, the United Nations Environment Programme (UNEP), and the United Nations Industrial Development Organization (UNIDO), GACERE offers a platform for stakeholders to advance a global circular economy and take forward partnership initiatives, including with major economies. With participation from 12 member countries and the EU, it’s clear that the call for circular economy investment and transformation is now at the world scale.

The path forward toward a circular tomorrow

Whether you are just beginning your transition toward a circular business mindset or your journey is already well underway, here are some critical questions to consider:

- How could circular strategies align with − and advance − our organizational vision and strategy?

- Which circular models could generate reciprocal value and incentive for our customers and our business?

- Could a model focused on domestic supply chain loops help us to reduce supply chain vulnerabilities?

- What are the timeline considerations for the development, pilot, trial and commercialization of new products or models?

- Have we identified existing and new potential partners who might share our sustainability objectives and have a similar risk tolerance for new ideas?

- What metrics and tools will we use to measure our progress?

- How will we define success internally, and are there relevant external recognition goals that we should aspire to?

Those able to successfully make the transition have significant opportunity to generate long-term value, per the Embankment Project for Inclusive Capitalism framework . New revenue streams, strengthened brand value and competitiveness as a supplier and an employer,23 and potential cost savings as traditional waste outputs are reused or on-sold are just some potential benefits.

For the less agile, the pace of change could soon challenge existing chemicals business models and revenues. As customer preferences transition toward recyclable products and packaging, and regulators strengthen their positions on single-use levies and extended producer responsibilities, investor and consumer enthusiasm for traditional take-make-waste businesses may wane.