EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients.

Products individually tailored to clients’ requirements

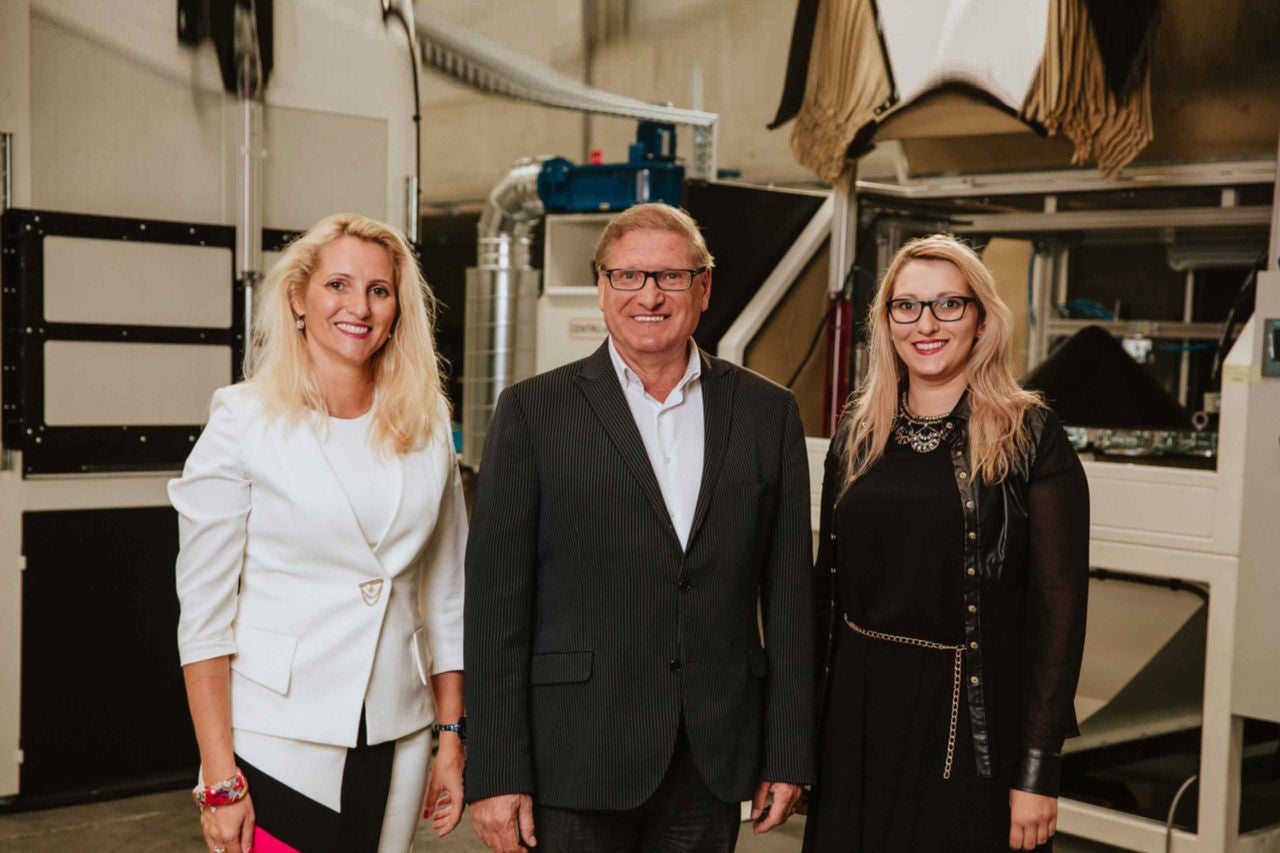

For over half a century, the FerroČrtalič family business has been engaged in developing solutions for the treatment of a variety of surfaces. Their main mission is to advise clients and provide them with the technology they need to resolve their specific problems. However, this is anything but an easy task, given the range of their requirements and often limited resources. Nevertheless, as the family maintain, nothing is impossible. ”It is important to have a good team that stands by you and shares the same energy. I believe anything is possible if you have the will.” The perseverance of the enterprise, which was nominated in 2003, 2004 and 2014 for a Slovenian Gazelle award (for the fastest-growing companies), is embodied by its director Mojca Črtalič Andolšek.

Downlad Family Business Slovenia 2016

Their products are used successfully to support the growth of companies worldwide, while keeping in step with new developments. Continuous innovation and research has placed the company among the world’s top suppliers of technological solutions in the field of surface treatment. They are committed to exceeding customer expectations, building honest partnerships and thus expanding their wider “family”. They are extremely eco-conscious, further strengthening their bond with the local community which, despite their globally-directed policy, plays an important part in their business ambitions: “We are closely tied to the local environment; this is our wish and also one of our values, and we are aware that you gain as much from the environment as you put into it. It is not difficult for me to do a good deed without requiring something in return,” says Mojca, who along with the company supports everything from local events to sponsoring various societies and individuals.

“Our dedication to our goals is synonymous with the successful family company, whose doors are never closed to motivated and ambitious employees. Last year, I made it clear that I want to recruit the best talent as this is the only way to achieve progress. Thus, employees who have demonstrated ambition and good results have been posted to more challenging jobs - both in the sales and the technical section as well as in the assembly department,” points out Mojca.

We never admit how many mistakes we make in tests before finally creating the perfect machine

Operating in industries including medicine, pharmaceuticals, foundry, nuclear decontamination, automotive and shipbuilding, they focus particularly on the most demanding of all, aerospace, where they are present with their Shot-Peening technology. They customize their solutions, often using sandblasting, hardening of surfaces in the aviation and automotive industries, plus conversion and cleansing of decontaminated surfaces. They mostly produce automated and robotic machinery that the customer can install and use to process a variety of materials and products. ”All our solutions are customized, made to order, as we develop solutions for individual products and specifically for the known customer. For example, if we manufacture products for foundries in Slovenia and Germany, they will both require very different products, since they have different needs, norms, requirements for surface structure and product forms. However, ultimately both of these products may have the same function or purpose,” says Mojca, explaining their customer approach. Her father Bojan adds: ”The FerroCrtalic equipment provides the solution a customer is searching for and we are compensated for our work by the sale of these products. But the key factor is the solution, which in economic terms has no price, while with regards to the time, economics, ecology and sustainability, it provides a competitive advantage to our customers and their businesses. This is a pure win-win situation.”

They are present at all major trade fairs around the world, including those in the USA, China, India, Israel, Egypt, Turkey, Iran and throughout Europe, as they believe this to be the only way to gain much-needed business partners and references. As Mojca points out, buyers often do not know exactly what they want: ”They imagine a solution that does not yet exist and for us this is the biggest challenge! What now? Let’s go inventing! Development and testing takes two, three months, sometimes half a year, or even longer,” until the customer is presented with what they really need or want. ”I have never wanted to sell something that customers didn’t really need. Identifying the customer’s predicament that our solutions must overcome is similarly demanding as is three or more months’ technological development of a machine. To manufacture something that our customer does not need would mean a bad reference for us.”

Half a century of family business

The origins of the company date back to 1964, when a young locksmith, Jože Črtalič, Mojca’s grandfather, decided to start his own entrepreneurial career. From his first workshop at Grm in Novo Mesto, they moved in the mid-seventies to Mačkovec in Novo Mesto, right at the time when their son Bojan graduated and began his career in the family workshop. In the 1990s, Jože, the father, gradually handed over the company reins to his son Bojan and his wife Slavojka. At that time, due to lack of space, the company moved again, this time to its current location at Sela pri Dolenjskih Toplicah. Today, the successful family story is pursued by Bojan’s oldest daughter Mojca and the younger daughter Anja, who is particularly successful in selling in the most far-flung markets, while their brother Jernej is in charge of the sister company at the former location in Novo mesto. “We are involved in the manufacturing of machinery, while my brother provides service activities - machine start-ups in customer locations, and the most demanding surface treatment on location. In addition, he performs testing with our machinery for end customers, and together we are building a strong and trusted family business,” says Mojca, explaining the complementary activities.

In the opinion of the Company Director, over 50 years of tradition is one of their major advantages: “Today, all over the world family businesses are highly appreciated. These types of businesses bring competitive advantage as the customer realizes that tradition and loyalty are important and that there is a reason for the company being present on the market for such a long period.” Currently the fourth generation of the family participates in the family business, while Mojca’s father Bojan, despite the fact that he has retired, continues to actively maintain contacts with business partners worldwide, and helps in the development of products and the more complex solutions. Mojca’s elder son Leo is a student and recipient of a company grant and thus he helps in the family business during the holidays. He is mostly involved in the administration, marketing and sales. He has recently edited the company’s website in Iranian because they sensed that it would be useful. Nevertheless, at this particular time he is reluctant to commit his career to the family business. “I want to prove myself, create something worthwile, and gain wider international knowledge. I would like to study Italian and other Latin-based languages, as I believe it is here that my talent lies. While my ideas are slightly different, I am aware of the importance of our company and I am proud and happy to offer a helping hand,” emphasizes Leo. The younger son Teo Tim is 10 years old and spends much of his time in the company. “This way, children can get the feel of the company, they can make contact with people and are a part of the business. Teo Tim is very technically minded and is interested in different aspects of the company business,” points out Mojca.

The family business hours: from midnight to midnight

What is the greatest challenge of a family business? Being able to adjust one’s time and workday. Mojca has no free time, because entrepreneurship is her way of life: “This is how I was brought up and for me this is normal. I cannot imagine working somewhere from seven in the morning to three in the afternoon…” Dishonesty, irresponsibility and broken promises are non-existent in the company. “They are not compatible with my values,” says Mojca, adding that she inherited perseverance and honesty from her parents. “Even if I don’t receive a salary, I will make sure the employees do. Our priorities are the employees and suppliers, and only then come family members and everything else. Development of the company is most important to us and therefore we are constantly investing in new technology.” So far, all offers to sell the company have been rejected, because they are committed to maintaining tradition. Nevertheless, who knows what the future may bring. “To assert with certainty that things will remain as they are, is absurd,” reflects a thoughtful Mojca.

Renowned names among their references

There are only five companies in the entire world that deal with the same technology as the FerroČrtalič family. Mojca sees this as their trump card, as they can take advantage of their size: “We are special because we are small and therefore more flexible to quickly adapt to changed conditions.

In addition, our prices are highly competitive.” While Mojca is in charge of the company’s operations and growth, her father’s expertise lies in engineering. In his words, challenges are food for the mind and soul: “The more complex the solution, the greater the challenge and it is the most demanding and difficult challenges that I most enjoy tackling. We are striving to create a good and loyal team, whose members share the same energy. I follow the same strategy.”

Their list of references includes notable names such as: Cimos Pipistrel, Akrapovič, Goodyear Dunlop Sava Tires, Carl Zeiss, Airbus, Volvo, Swarovski, Krka, Sandoz, as well as General Electric and Pratt & Whitney from the United States, the Kozloduy Nuclear Power Plant, Elan, Renault and VW. “We agree transactions with these multinationals which have branches all over the world. When you complete one installation, opportunity knocks elsewhere, because companies want similar solutions at their facilities in other locations,” explains the Company Director. They are financed mainly from their own resources, and all the profits are invested in the development of technology, products and the company, as well as in marketing. The only loan they have ever had to raise was on account of the new facility. The next milestone they have set regarding the volume of business is five million euros in revenue and at least 10% annual growth, although their main purpose is not financial. They want to become a reliable and recognizable global company with customized solutions and the flexibility to meet customer demand

Summary

FerroČrtalič in a nutshell: personal responsibility, diligence, professionalism, family, honesty.