EY refers to the global organization, and may refer to one or more, of the member firms of Ernst & Young Global Limited, each of which is a separate legal entity. Ernst & Young Global Limited, a UK company limited by guarantee, does not provide services to clients.

Their engineers are their business advantage

Mertik family from Brezovica pri Ljubljani has lived and breathed their family business, MI Elektronika, for a good three decades. Now one of the largest EMS providers of printed circuit board (PCB) assemblies in Slovenia, the company began as Ignac Mertik’s side business in the 1980s. Around two years ago, he passed the reigns to his daughter Sonja, who has followed in his footsteps with great success.

Today the family enterprise employs 50 people and last year they made €7 million in revenue with €1.5 million profit.Their plans, which include employing around 200 additional people in the next 10 years, are ambitious but realistic, considering the company’s dynamic revenue growth of over 250% in the past five years.

Our policy is to pay our workers fairly, as this is the only way to get what you want from them. Only fair payment deserves to be rewarded with fair work

Last year MI Elektronika achieved revenue of €7 million, with €1.5 million profit.

The story of an entrepreneur from the periphery who succeeded in the mainstream

Ignac was born in Lendava, in the northeast of Slovenia, to a family with a long farming and winegrowing tradition. “My great-grandfathers were winegrowers and my father continued that tradition so that we became one of the largest winegrowers in that part of Slovenia, when it had become big business. Of course, we could not do all the work by ourselves, which is why we hired workers, sometimes as many as 25 per day. I can say at entrepreneurship has always been in my family DNA,” recalls Ignac.

In the mid-eighties, Ignac began building his entrepreneurial future, but he had already laid foundations elsewhere. After high school, he first worked and gained experience at the Elma company in Ljubljana and in the early eighties he accepted an invitation to work for IMP Avtomatika, which later become Danfoss Trata. He stayed with them for six years, first as a technologist and later in the sales department.

In 1986, he finally decided to pave his own way and founded a small electrical engineering workshop, which eventually grew into MI Elektronika. Their first client was IMP Avtomatika, for which they made central heating regulators and sensors. The break-up of Yugoslavia was a difficult period for many enterprises and MI Elektronika had to let several employees go, but their fortunes improved after 1996, when they began manufacturing their own products.

Their main advantage is represented by their 32 engineers who integrate their knowledge into the assemblies, which are sold in the global market as Slovenian knowledge.

International raw materials combined with Slovenian knowledge

Today, MI Elektronika is one of the largest companies offering PCB assembly services in Slovenia. While these represent their main product line, they also provide final mounting of the assemblies, manufacture cables and develop and produce their own EMI filters. Some years ago they also began developing and manufacturing LED lights.

MI Elektronika provides components for PCB assemblies to the most discerning clients in the fields of medicine, welding technologies, aeronautics and gambling. They buy raw materials on the international markets, but all their knowledge comes from Slovenia, as Ignac points out: “Our greatest advantage comes from our 32 engineers who integrate their knowledge into the assemblies we produce. These are then sold on the

international market as Slovenian know-how. The most challenging products are assemblies for the medical industry, which are very technologically- demanding and usually only ordered in small quantities.” The components made by MI Elektronika are also used in the fields of stomatology and facial care, which increasingly use laser-based technologies.

MI Elektronika directly exports around 8% of its production, but through their clients as much as 90% of their products are ultimately employed abroad. “Our largest markets are the USA, South Korea and China,” says Ignac. In addition to several Slovenian awards and recognitions — the 2014 Central Slovenian Gazela Award, the 2018 Delo Business Star Award and 2019 Bronze Slovenian Gazela Award — they also received the “Creators of the century” award from Perspective, the International Economic Forum (IEF) with 1178 members from nine southeastern and northern European countries. This award put MI Elektronika among the 300 most promising companies from this region.

“Buyers who were very restrained at the start of the crisis have returned and we are back to working at full strength for 10 hours per day.

The grandson that kept the company in family hands

Ignac never doubted that his daughters, Sonja and Tina, would enter the family business and today they both work in the company. “I raised my children with an entrepreneurial spirit,” points out Ignac. “I never gave my daughters pocket money, so they had to earn it. If they had some free time after school, they could work at the company, write down their hours and they got paid,” he explains. “This is how my sister and I bought our first Poni bicycle,” recalls Sonja.

Today Sonja’s son Alen also works part-time at the company. His was the one voice to convince Ignac that the company should stay in the family. “I once got a tempting offer to sell the company. But when my grandson reminded me I had promised him that he too could work in the family company, the deal was off,” laughs Ignac.

Before Sonja, who studied economy, took over the family enterprise, she gained significant experience in the Ljubljana sales department of multinational company. “I gained a lot of experience related to working with people and I saw how things work in northern Europe, where everything is very organized,” she explains. Was she afraid to put on her father’s shoes? “He still makes the important decisions,” is her answer. Ignac says he stays out of the day-to-day operation of the company, but as its Authorized Representative he still helps with the finances and takes care of strategic projects. His younger daughter, Tina, is a chemical engineer who controls the company’s sorting and storage of materials.

Expanding the pool of clients in response to the coronavirus

What business results can MI Elektronika expect in 2020, after the coronavirus pandemic has altered almost all aspects of the economy? Ignac says that all things considered, results will not be much worse than last year. He is very happy that the mood in the company is returning to its pre-pandemic optimism. “Buyers who were very restrained at the start of the crisis have returned and we are back to working at full strength for 10 hours per day,” he explains. They have also decided to put more energy into maintaining relationships with existing clients and finding new ones. “During the pandemic we realized that we needed to expand our client pool, which is why we gave new powers to our marketing department,” adds Sonja. Both also point out that the coronavirus showed them how important it is to react quickly.

Their policy is to pay their workers fairly, as this is the only way to ensure optimum performance.

Headcount of 250 by 2030

One of the strategic projects MI Elektronika started even before the coronavirus pandemic is the construction of a new state-of-the art plant for PCB assemblies in Logatec. They plan to move their existing production to the new plant with the aim of having 250 employees by the end of the decade. “Our current building in Brezovica became too small,” says Ignac.“A small company with a few dozen employees has to fight really hard to get business, but as a company with several manufacturing lines, we can work with large clients. Our aim is to have 15 manufacturing lines,” he says, explaining the company ambitions. The new location will also expand their storage capacities, which are now at their limit.

At MI Elektronika they know that the knowledge of their employees is the key to their added value. They also firmly believe that employees deserve to be rewarded. “Our policy is to pay our workers fairly, as this is the only way to get what you want from them. Only fair payment deserves to be rewarded with fair work,” points out Ignac, who is very proud that hardly anyone wants to leaves their company.

At least as important as fair payment is also education and the systematic training of younger generations. MI Elektronika offers internships for students of faculties and high schools in Ljubljana. They keep the best students and offer them employment. They realize that young knowledge “makes the world go round”, which is why they regularly collaborate with young researchers from the Technology Park Ljubljana.

Ignac Mertik, owner

Company name: MI Elektronika, d. o. o.

Number of employees (2019): 50

Net sales revenue (2019): €7.1 million

Interviewees:

Ignac Mertik, Founder and Authorized Representative

Sonja Rastoder, Director

Summary

MI Elektronika in a nutshell: knowledge and development, commitment, social responsibility, entrepreneurship, family.

Related articles

The Rast Tim family enterprise found its market niche in delivering crates of fruit and vegetables.

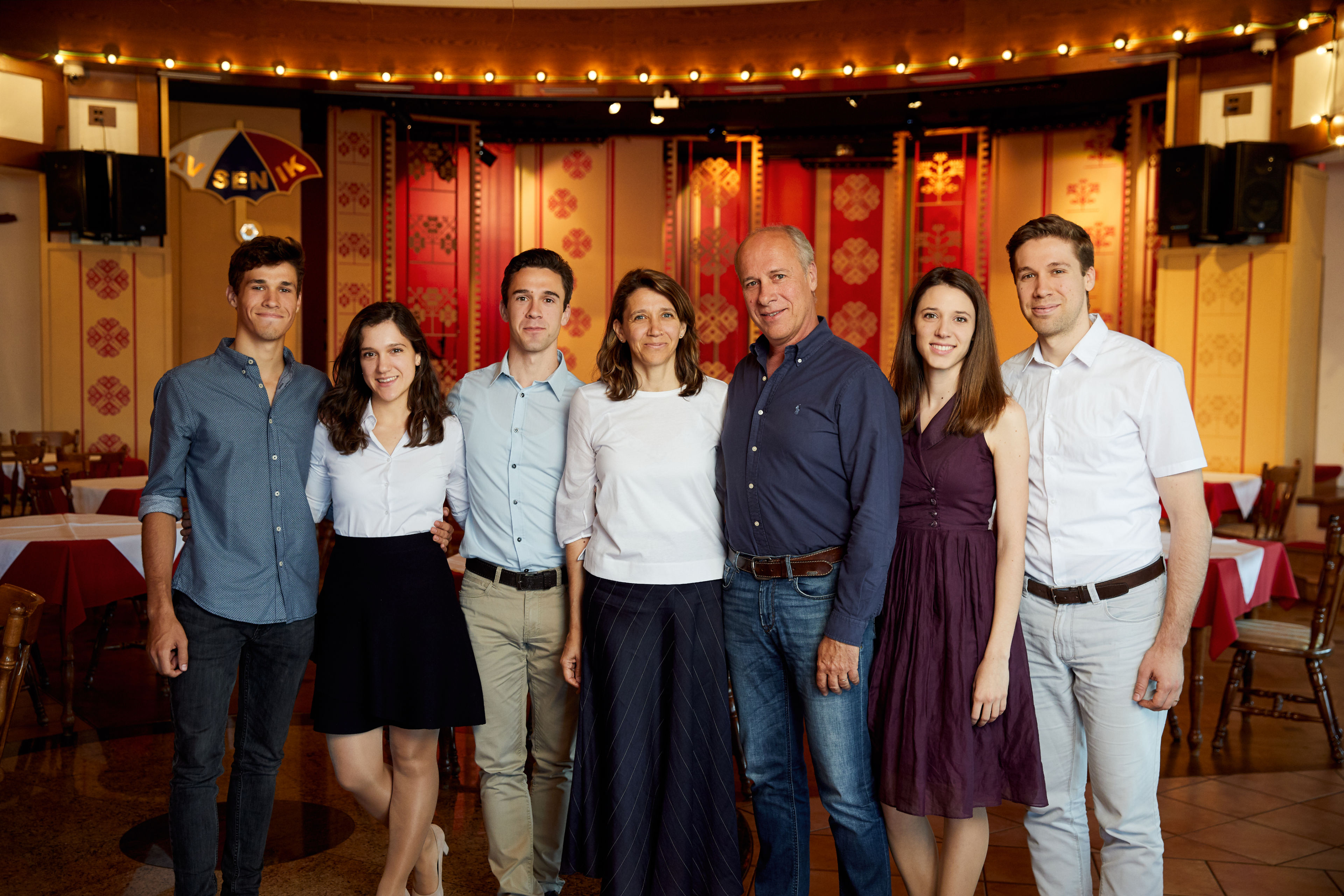

The Avsenik name is more than just a synonym for folk music. It embodies a company and a family in which hospitality services are deeply intertwined with music.