From his father-in-law's workshop to a facility covering an area of 5,200m²

The founder and executive manager Rudi Kronovšek has been working in the field of heat pumps for more than 40 years.

After he finished his studies, he gained employment as a mechanical engineer at Gorenje, which in the 1970s was the centre of heat pump production. In 1990 he registered his own company Termo-tehnika, which has been active since 1993. In his father-in-law’s workshop of just 50m2 he firstly manufactured refrigerating devices for wineries and wine storage. “This proved to be a niche product and the company grew rapidly. Only two years later we ventured into my familiar field of heat pumps,” describes Rudi. Since then the company has trodden a difficult but very successful path. If at first annual sales reached only 100 pumps, today they sell an impressive 7,000 per year.

The company gradually expanded its product range. In addition to pumps, they began manufacturing cooling chambers, drying equipment, industrial cooling devices and systems. Over time special attention was dedicated to the development of cooling system technology used in wine manufacture. These systems are now used in several hundred small wineries and also an impressive number of larger ones.

In the second half of the 90s they extended their range with modern, beautifully designed and functional products, increased the number of employees and focused on promotion and marketing. Their hard work has brought good results as the quantities sold have increased annually by between 30% and 40%. The increase in the volume of orders and production was followed also by a sharp increase in the number of employees, and today the company employs a total of 56 staff. Another milestone was reached in May 2015 when, after a decade of hard work, they finally moved into a new 5,200m2 production and office building. This has secured the conditions required for further growth and development of the family business.

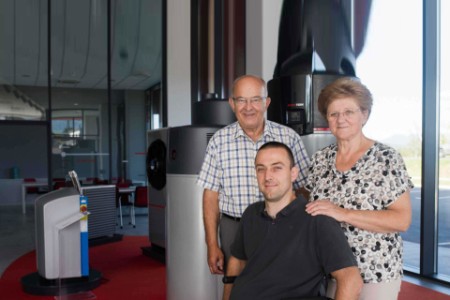

After several years of testing and certification of devices at the SIQ institute for the safety and compliance of devices, in 2004 they signed a contract for the supply of heat pumps to one of Europe's largest manufacturers of water tanks, Austria Email. Four years later Rudi handed over the helm to his son Bogdan, computer and information sciences engineer, although he remains active in the company.

In 2013, the company achieved another milestone when they produced the 40,000th heat pump. The achievement was celebrated with the introduction of their new brand Kronoterm, the name of which reflects the family's commitment to the company. That particular year was exceptional in all respects, as they reached €12 million of turnover and, according to Rudi, the continuing trend is positive. Now, as the economy slowly recovers, they expect to generate a turnover of €9 million in 2015.

Quality with no compromises

The company's mission is the further development, manufacture and marketing of high-tech devices for energy saving and environmentally-friendly heating and cooling systems. Dedication is their core value, while their reputation is based on professional approach and their expertise.

With sales of more than 6,000 sanitary, and over 1,000 heat pumps, for many years they have been the leading Slovenian company in this field. In addition, they are increasing their presence in international markets, so that foreign sales account for half the manufactured products. Their most important markets are Austria, where the company has been present for more than 10 years, Italy, Switzerland and France. Despite increased price pressure from cheap Chinese products, they remain optimistic, due to their strong commitment to quality. “Our products are top-notch. We use only the best components and do not skimp on quality,” assures Bogdan.

A team of highly skilled engineers ensures continuous improvement of serial devices and the development of new generations of heat pumps and specific industrial systems. They use advanced technology, which includes sophisticated tools used in the design, construction and testing of devices. Like some of the world’s most renowned companies, the business is closely involved in the development and enhancement of certain components used in refrigeration systems.

Strong commitment to the family business

“I became involved in the family business by pure chance. Then, to my surprise, I became enthusiastic about it. I realised I had talent as well as knowledge, which I had gained by reading literature,” says Rudi, who sees success as an advantage of a family business. “If you are successful, it gives you great incentive and even greater impetus.” Rudi and his wife Cvetka each own 50% of the company. Although his wife's involvement is comparatively small, Rudi makes sure she is kept informed of all matters relating to the family business.

In addition to Rudi's son Bogdan, Rudi's brother-in-law, Dean Besednjak is also actively involved in the company as assistant director, while Rudi's other son and daughter are not employed by Termo-tehnika. His daughter is a professor of mathematics and she chose not to follow in her father's entrepreneurial footsteps, while his other son has his own company engaged in the automotive business. In contrast, Bogdan is enthusiastic about continuing the family business and last year he ranked among the three finalists for the Young Manager 2014 competition organized by the Managers’ Association of Slovenia. So where does he see the advantages of a family business? “You put your very heart into the work, accept a different working routine, have evening meetings at home and often return to work after the meeting.” On Saturday and Sunday mornings, all three of us are usually here in the workshop. While this is not much good for family life, it is certainly good for the company,” concludes Bogdan.

“I became involved in the family business by pure chance. Then, to my surprise, I became enthusiastic about it. I realised I had talent as well as knowledge, which I had gained by reading literature,” says Rudi

Among the best of the Gazelles

Investment in knowledge and development, advanced technology, strategic partnerships, quality and flexibility, technical and highly skilled service support, are values that determine Termo-tehnika and are also their advantages.

In over 25 years the company has received numerous professional and business awards. Among the latter, they are most proud of the award for the company’s successful and stable growth, the 2007 Golden Gazelle of the Savinjsko-Zasavska region. For the second year in a row the company has been granted an A credit rating due to its financial stability. Among the prizes for innovation and development they are most proud of the silver and bronze guild and the ranking of the highly efficient ECO heat pump series in the top three environmentally friendly products in 2010.

They do not speculate with numbers

Although some time ago certain parties came up with an initiative to move the company elsewhere, they remain firmly anchored in their local Braslovče. “I am a great supporter of the home location, so I insisted that the company business stays here. I got used to having the company close; this is probably typical of all companies where one spends practically 24 hours a day at work,” says Rudi. Bogdan agrees with his father: “We are very much locally-oriented. I often tell employees: ‘If the company is sound and healthy, you will also have the opportunity to employ your neighbour, partner, or child.’ This is not a promise, but an option.” The average monthly gross wage per employee is €2,000, which is 25% above the Slovenian average. Last year the company generated above-average added value per employee of €65,000. How do they do it? “One of the factors is that we do not speculate with the numbers,” says Bogdan.

As Bogdan is enthusiastically dedicated to managing the entire company, Rudi assists in recruitment: “Annually between 200 and 300 fitters are trained in our training facilities learning about refrigeration technology and our systems. We are passing on our knowledge to new talents across the entire country.”

Laboratory for ‘top-notch’ products

The company is currently completing construction of a modern laboratory. “The laboratory, built to the most advanced specifications and with first-class equipment, will help us obtain a certificate, which will allow testing of our own products to achieve internationally valid results,” says Bogdan. The standards are changing every year, and the only things that remain constant are the complicated processes and sky-high price of device testing. Having this ultra-modern laboratory and certificate will allow us to test our own, as well as other devices. “The new laboratory and cutting-edge technology will allow for further production of ‘top-notch’ products,” explains Bogdan.

Summary

Termo-tehnika in a nutshell: “We put our very heart into every product to ensure top quality.”